|

|

|

HYBRID HAPTIC DEVICES

haptic interface design concepts

A.I LAB

ai.stanford.edu

The continuing emergence of computer haptics for training, industrial and entertainment applications has increased the need for cheaper, safer and smaller tactile display solutions. Today most force-feedback interfaces come in the form of small robot manipulators: these systems use electrical motors to generate forces and joint sensors to measure spatial position. The main difference between them resides in their way of operating: while robots are generally programmed to perform active tasks such as moving to a desired position or carrying a load, haptic devices are moved directly by the operator and are programmed to constrain hand motion. The use of electrical motors to reproduce high fidelity tactile sensations has also introduced the risk of striking the user; with rare exceptions, safety concerns have also limited motor-actuated haptic devices to small workspaces. Many actuation methods using brakes instead of motors have been developed to improve safety and stability. Due to the mechanical nature of brakes, it has been a difficult task to design a brake actuated interface which can generate forces with arbitrary directions and amplitude so that complex shapes with texture properties can be rendered in a realistic manner.

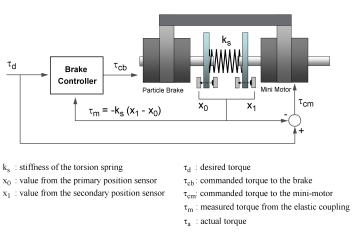

To address these problems we developed a new actuation approach composed of brakes, springs and micro motors. In this new actuation scheme, mini-motors are directly coupled to the links of the device to produce low forces at high frequencies (i.e. surface textures, small impacts). The higher forces are generated by connecting in parallel to the mini-motors a set of particle brakes coupled with torsion springs. When the brakes are engaged and the user moves the end-effector, energy is stored into the torsion spring and a force is perceived at the user handle. On a multi degree-of-freedom haptic device, the force is a result of the contribution of each torsion spring. The direction and magnitude of the force can be reoriented or reduced by release the brakes in a controlled manner. By efficiently controlling both the brakes and the mini motors it is possible to render virtual shapes and textures in a very realistic manner and with much less electrical power compared to a classic motor-only actuation approach. The overall safety is also highly improved because mini motors cannot strike the operators with high active forces.

A New Actuation Approach for Haptic Interface Design

F.Conti and O.Khatib, The International Journal of Robotics Research 2009;28 834-848

|

|

|